Have you heard of the Explosion Proof Electric Forklift?

You are probably familiar with the two basic types of forklifts – the gas-powered and the electric forklift, which are both helpful in lifting heavy loads. There are also different types of lift trucks that are classified according to specific applications. These are the standard forklifts commonly seen in construction sites, warehouses, logistics, or distribution centers.

What if we tell you there is another type of forklift – a special type that is spark-proof and resistant to any explosion? Many industries require the use of special forklift trucks that can withstand extreme working conditions without compromising safety. And this type of machine is known as the explosion-proof industrial forklift.

In this post, we’ll go over all the information you need to know about explosion-proof lift trucks. To help you navigate this article easily, you may click on the link to jump to the section that’s more useful and interests you most.

- What is an Explosion Proof Forklift?

- What is Special about Explosion Proof Lift Trucks?

- Who are the Primary Users of Flameproof Forklift?

- Why Should You Use an Explosion Protection Forklift Truck?

- What are the Benefits of Using an EX Forklift?

- How to Determine Whether a Workplace Needs an EX-Rated Lift Truck?

- Does Kran Offer an Ex-Proof Forklift Rental Service?

- When and Where to Use Kran’s Ex-Proof Forklift?

What is an Explosion Proof Forklift?

An explosion-proof (EX, Ex, Ex-proof, Ex-schutz) forklift is designed for use in hazardous and explosive environments. This equipment is unique and one of a kind since it is built to eliminate any ignition and fires and perform in tough environments so that operators can execute tasks safely.

Explosion proof forklifts are somehow novel to the majority because the production and manufacturing of this type of forklifts are not as extensive as the typical forklift. Still, many industries and businesses often require the use of this type of forklift in their workplace. There are two ways to acquire an Ex-proof forklift: (1) buy a forklift that is built specifically to be explosion-proof or (2) convert a regular forklift into a flameproof forklift. Both options are recommended; however, buying one might be more difficult due to low availability in the market. Converting or renting an explosion proof forklift is more accessible and affordable.

What is Special about Explosion Proof Lift Trucks?

A flameproof forklift has many unique features as compared to a standard forklift truck. It is the only type of forklift that can withstand explosions and perform in dangerous job sites with ease. This equipment is Explosion Proof (EX) rated to control temperature, static, and other factors that can cause hazardous explosions. The EX forklift is equipped with a Pyroban system which includes monitors that shut down the machine if hazardous fumes, smoke, or gases are detected present in a potentially explosive environment which other forklifts do not offer.

In addition, the electrical components of an ex-proof forklift are totally sealed and protected to avoid combustion due to electric spark. The electric gear mechanisms are typically converted to hydraulic systems and standard lighting systems are replaced with flameproof forklift lighting. Aside from it, the tires are electrically conductive. Metal parts that could spark on contact are also covered with spark-resistant material, such as brass or stainless steel.

Who are the Primary Users of Flameproof Forklift?

Regular forklifts are used primarily in warehouses and markets, while explosion-proof forklifts are necessary equipment in explosive and hazardous environments. Many workplaces may contain hazardous materials or have activities that can generate a potentially explosive atmosphere. The industries that typically use the Ex-proof forklift are primarily involved in manufacturing, handling, processing, and storing flammable or unsafe materials such as perfumes, cosmetics, paints, medicines, botanical products, and synthetic materials like rubber. Thus, paint factories, sugar mills, and ordinance facilities are popular users of this type of machine. Industries that handle materials that produce combustible dust like dried hay, starches and pastes, potatoes, and grain also require Ex-proof lift trucks.

Why Should You Use an Explosion Protection Forklift Truck?

Various industrial facilities work in hazardous conditions; these conditions can lead to explosions or other similar hazards. A standard non-flameproof forklift truck has multiple possible ignition sources; thus, using it in these conditions is highly dangerous.

That is why it is necessary that forklift trucks, both diesel or battery electric, must be EX compliant.

Thousands of businesses rely on explosion-protected forklifts to handle materials and products within hazardous areas where even the smallest spark could cause ignition. The explosion-proof enclosure in the forklift helps prevent internal explosions from spreading out in the ambient environment.

Here are some of the hazards present in an unprotected forklift truck operating in a potentially explosive atmosphere:

- Unprotected electrical apparatus

Unprotected electrical and electronic equipment can become a source of ignition as they can cause powerful electrical sparks. Lights and sounders can generate electrical sparks. - High surface temperatures

Heat can ignite an explosive atmosphere. During regular operation, a battery electric forklift may cause ignition from high surface temperatures. Batteries, engines, motors, brakes, and other forklift components can get hot and emit sparks. - Electrostatic discharge

Static build-up and friction can generate enough heat to cause ignition. There are many possible ignition sources on a forklift truck: rolling tires and frequent contact with plastics can build up dangerous levels of electrostatic charge. The seat, armrest, steering wheel, and levers that are in constant contact with the operator are also possible sources of ignition. - Mechanically generated impact or friction sparks in forks

Even forks can cause mechanical sparking due to the friction during normal operation. If the forks strike another surface, they can create (mechanical) sparks with enough energy to cause ignition. - Engines

A diesel engine-powered equipment also has ignition sources such as high engine and exhaust surface temperatures. If the gas or vapor present in the atmosphere gets mixed with the air and diesel fuel, the engine (at a powerful speed) might get out of control, resulting in overspeeding or the engine’s failure. This overspeeding can generate combustion in the engine inlet and exhaust which could ignite the surrounding atmosphere.

What are the Benefits of Using an EX Forklift?

Now that you’re already aware of the possible ignition sources present in a regular forklift, you understand the importance of implementing explosion-proof enclosure in hazardous locations which is to ensure the safety of workplace operations. We have listed six (6) important advantages of using explosion-proof electrical forklifts:

Ensures Safety

Many industrial facilities have a hazardous environment; thus, it is essential to use explosion-proof equipment to create a safe working environment. Using an Ex-proof forklift can guarantee that your employees remain safe and also minimize potential damages.

Improves Operational efficiency

As a corporation or organization, it is your responsibility to ensure the safety of your employees. Obviously, no employee wants to work in an unsafe environment or expose themselves to a workplace where a potentially explosive atmosphere is present. Your employees would be at ease knowing that they are working at an organization that values their safety. Hence, they would be able to focus on their job and increase company productivity.

Environment-friendly

Ex-proof forklifts powered by a lithium iron-phosphate battery are already available in the market. There is a considerable advantage when using this type of battery-powered machine; it is efficient in terms of energy and emissions because lithium batteries produce zero exhaust emissions. Thus it is carbon-free and energy-saving. These characteristics make it a more reliable, efficient, and viable alternative to traditional explosion-proof diesel or electric trucks.

Easy to maintain

When it comes to maintenance, Ex-proof forklifts with lithium batteries are easy to maintain compared with the lead-acid batteries that are often associated with management and charging problems. It saves more than 40% of electricity and has a longer battery life span. The quick charging mode feature makes it ideal to use for multi-shift operation.

Saves on fuel costs

A standard gas forklift constantly needs fuel, and this adds to the company’s daily or annual expenses. Unlike other regular forklifts, the explosion-proof electric forklift is powered by a battery, thus reducing fuel expenses.

Strengthens Reputation

Strict compliance with safety regulations helps in maintaining excellent safety records and sustaining the company’s reputation. This includes using explosion-proof equipment. You must ensure that you provide a safe and protected environment for your workers; this will encourage people to work with your company.

How to Determine Whether a Workplace Needs an EX-Rated Lift Truck?

Hazardous areas are defined as “any place in which an explosive atmosphere may occur in quantities such as to require special precautions to protect the safety of workers,” according to the Dangerous Substances and Explosive Atmospheres Regulations 2002 (DSEAR).

Any workplace will require an ex-proof forklift if combustible gases or dust are present in the atmosphere.

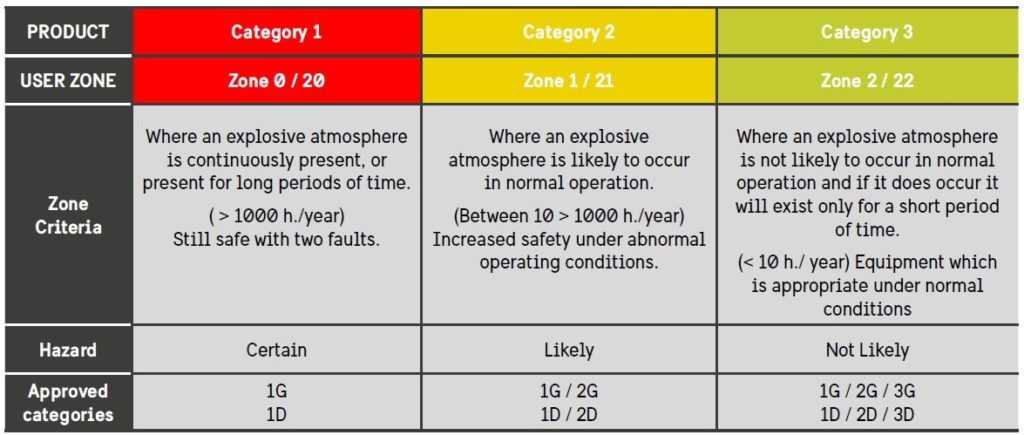

ATEX, an acronym derived from the words “Atmospheres Explosives,” refers to the European Directives that cover manufacturing standards for controlling explosive atmospheres. These directives divided the areas with potentially explosive atmospheres into zones according to the frequency of the occurrence and duration of a potentially hazardous risk – so that only appropriate certified equipment can be used there.

To determine potentially hazardous location, it has been divided into several zones:

- 0, 1, 2 for Gas, Vapor, Mist

- 20, 21, 22 for Dust

ATEX zones for gases/vapor:

- Zone 0: areas where an explosive mixture is continuously present or present for long periods.

- Zone 1: areas where an explosive mixture is likely to occur in normal operation.

- Zone 2: areas where an explosive mixture is not likely to occur in normal operation, and if it occurs, it will exist only for a short period.

ATEX zones for dust:

- Zone 20: areas where an explosive mixture is continuously present or present for long periods.

- Zone 21: areas where an explosive mixture is likely to occur in normal operation.

- Zone 22: areas where an explosive mixture is not likely to occur in normal operation, and if it occurs, it will exist only for a short time.

With the ATEX Directive, every Zone is associated to a Category, and each electrical equipment is classified according to these categories (to indicate the areas where it can be safely used).

Here are the six categories:

The categories 1G, 2G, and 3G are classes for gas explosion protection (G = Gas).

- Category 1: Equipment under this category can be used in zones 0, 1, and 2

- Category 2: Equipment recommended for use in zones 1 and 2

- Category 3: Equipment acceptable for use in zone 2

The categories 1D, 2D, and 3D are groups for dust explosion protection (D = Dust).

- Category 1: Equipment under this category can be used in zones 20, 21, and 22

- Category 2: Equipment recommended for use in zones 21 and 22

- Category 3: Equipment acceptable for use in zone 22.

Does Kran Offer an Ex-Proof Forklift Rental Service?

In addition to our wide range of rental equipment and machinery, Kran also provides explosion-proof forklifts category 3G for short-term and long-term rental. The features and attributes of this Ex-proof equipment include:

- Surface temperature limitation to ensure that the motors, brakes, electrics, and other components stay below the auto-ignition temperatures

- The armrest and seat are covered with antistatic fabric.

- Forks covered with spark-proof material

- EX enclosures for all electrical components

- Conduits that can withstand great temperature and pressure levels

- Static conductive tires which prevent static ignition

- Explosion-proof enclosures for arcing and sparking truck components

- Monitoring of surface temperatures

- STILL RX 60-40: Ergonomic Design for A Comfortable and Safer Workplace

Our STILL RX 60-40 Explosion Proof Electric Forklift truck guarantees safe warehouse operations while handling potentially hazardous materials in all areas, including ones that are not classified as potentially dangerous but should be protected against the risk of explosion. It is ideal for use in small spaces due to its compactness and extreme maneuverability, allowing operators to work in narrow aisles. In addition to being extremely compact, the truck is innovative, flexible, and multi-functional, which is ideal for multiple-shift operations (also, thanks to its high battery capacity and lateral battery changing). Aside from being an EX rated truck, it also offers optimum safety due to its low center of gravity and outstanding driving stability.

Inside the truck is an enclosed, comfortable driver’s cab that can be individually set up and has numerous storage compartments.

It has a high driver’s seat and a large viewing window on all sides allowing operators to have a good view while carrying bulky loads.

Aside from the most important feature of this machine, which is explosion-proof (Pyroban), what’s great about this equipment is that it offers an emission-free drive and maintenance-free engines for driving, steering, and lifting.

Another feature is the hydraulic accumulator in the lifting cylinder to attenuate pressure peaks in the hydraulic system and the side shift that allows the load to be moved from side to side, reducing handling time and improving maneuverability.

This 4-wheel counterbalance forklift has a maximum load capacity of 4000 kg and capable of carrying goods effectively. It has a powerful electrical drive that has a very low environmental impact and high handling rate.

When and Where to Use Kran’s Ex-Proof Forklift?

Zone 2-identified places are the recommended working zones for our forklift, where flammable and volatile gas or vapor is unavoidable. The workplaces under this zone include:

Hardware and storage

Repository places like hardware and storage areas for flammable materials such as paints, varnishes, and inks always require a specialized forklift. Some paints are flammable, such as aerosol and oil-based paints. On the other hand, water-based paint, including latex, acrylic, or vinyl paint, and many artists’ paints are not flammable. However, sometimes, this typically non-combustible type of paints turned out to be explosive or hazardous as they include small amounts of formaldehyde or ammonia, which is why it is best to consult the product manufacturers before considering the materials safe.

Laboratory supply manufacturers

EX forklifts assist medical supply manufacturers in the safe handling of reactive materials like chlorine and glassware. Many flammable materials are present in laboratories. Flammable liquids are volatile in nature and release vapors at high temperatures, which can ignite in the presence of sparks, flames, or hot surfaces. Examples of these are acetone, ether, methyl ethyl ketone, methyl isobutyl ketone, alcohols, cyclohexanone, etc.

Combustible solids include sodium, lithium, magnesium, and aluminum. Gases such as hydrogen, acetylene, propane, methane, etc., can be flammable when these come into contact with an oxidant and ignition source.

Cosmetic Production

Ex-proof forklifts assist in the production of cosmetic products by safely handling materials such as alcohol, wax, and other additives. It is required to handle and transfer materials with great care. Mishandling can have serious consequences and cause significant problems such as serious health risks, potential inventory loss, and facility shutdown.

Agricultural Chemicals Production

Chemicals like pesticides and fertilizers are manufactured, processed, and stored in a hazard-prone environment, thus using an explosion-proof forklift is required. Although most fertilizers are quite stable, there have been instances of fires and explosions with substances such as ammonium nitrate. Like other inorganic nitrates, ammonium nitrate is an oxidizing agent that can increase the intensity of a fire.

Another hazardous substance is anhydrous ammonia which can cause severe burns upon contact. Contact with the liquid ammonia can cause loss of sight, irritation of skin, eyes, and severe injury of the respiratory membranes.

Even agricultural products can become combustible under specific situations. Examples of these materials are egg whites, powdered milk, cornstarch, sugar, flour, grain, potato, and rice.

Drying Rooms

Drying rooms need an Ex-proof forklift since this environment possesses the optimum conditions for a fire (high fire risk). Dryers present combustion hazards from hot gases or particles entering the dryer. The vapor or particles can be generated from the combustion process, inefficient burning of solid particulate fuels, or recirculation of the airstream.

Painting Booths

Even vehicle painting shops often have explosion-proof forklifts to help carry materials without any hazards. Certain paints, lacquers, varnishes, shellacs, solvents, and thinners are very flammable. Other materials such as papers, rags, and wastes can also ignite under certain conditions.